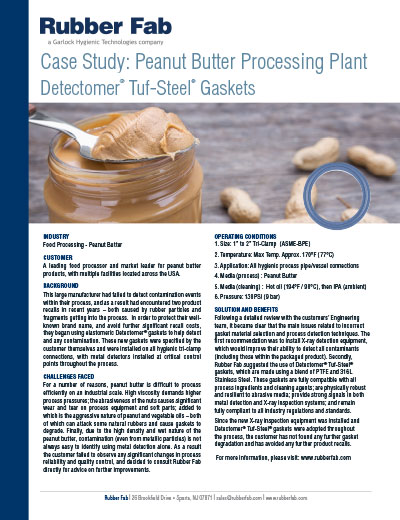

Detectomer® Tuf-Steel® Gaskets in Peanut Butter Processing

This food processing plant benefitted from Detectomer® Tuf-Steel® by reducing product recalls

INDUSTRY: Food Processing – Peanut Butter

CUSTOMER: A leading food processor and market leader for peanut butter products, with multiple facilities located across the USA.

BACKGROUND: This large manufacturer had failed to detect contamination events within their process, and as a result had encountered two product recalls in recent years – both caused by rubber particles and fragments getting into the process. In order to protect their wellknown brand name, and avoid further significant recall costs, they began using elastomeric Detectomer® gaskets to help detect and any contamination. These new gaskets were specified by the customer themselves and were installed on all hygienic tri-clamp connections, with metal detectors installed at critical control points throughout the process.

CHALLENGES FACED: For a number of reasons, peanut butter is difficult to process efficiently on an industrial scale. High viscosity demands higher process pressures; the abrasiveness of the nuts causes significant wear and tear on process equipment and soft parts; added to which is the aggressive nature of peanut and vegetable oils – both of which can attack some natural rubbers and cause gaskets to degrade. Finally, due to the high density and wet nature of the peanut butter, contamination (even from metallic particles) is not always easy to identify using metal detection alone. As a result the customer failed to observe any significant changes in process reliability and quality control, and decided to consult Rubber Fab directly for advice on further improvements.

OPERATING CONDITIONS:

- Size: 1” to 2” Tri-Clamp (ASME-BPE)

- Temperature: Max Temp. Approx. 170°F (77°C)

- Application: All hygienic process pipe/vessel connections

- Media (process) : Peanut Butter

- Media (cleaning) : Hot oil (194°F / 90°C), then IPA (ambient)

- Pressure: 130PSI (9 bar)

SOLUTION AND BENEFITS: Following a detailed review with the customers’ Engineering team, it became clear that the main issues related to incorrect gasket material selection and process detection techniques. The first recommendation was to install X-ray detection equipment, which would improve their ability to detect all contaminants (including those within the packaged product). Secondly, Rubber Fab suggested the use of Detectomer® Tuf-Steel® gaskets, which are made using a blend of PTFE and 316L Stainless Steel. These gaskets are fully compatible with all process ingredients and cleaning agents; are physically robust and resilient to abrasive media; provide strong signals in both metal detection and X-ray inspection systems; and remain fully compliant to all industry regulations and standards. Since the new X-ray inspection equipment was installed and Detectomer® Tuf-Steel® gaskets were adopted throughout the process, the customer has not found any further gasket degradation and has avoided any further product recalls.

Sanitary Gaskets

Sanitary Gaskets Detectomer® Family of Products

Detectomer® Family of Products O-Rings

O-Rings Sanitary Hose & Hose Assemblies

Sanitary Hose & Hose Assemblies Hose Fittings & Adapters

Hose Fittings & Adapters Tubing

Tubing Sight Gauges

Sight Gauges Sanitary Clamps

Sanitary Clamps Compression Control Products

Compression Control Products Pump Replacement Parts

Pump Replacement Parts Carton Filler Replacement Parts

Carton Filler Replacement Parts Sanitary Tube Supports

Sanitary Tube Supports Food Processing Products

Food Processing Products Cheese Processing and the Dairy Industry

Cheese Processing and the Dairy Industry Sanitary Seals & Hoses for the Beverage Industry

Sanitary Seals & Hoses for the Beverage Industry Pet Food Processing Industry

Pet Food Processing Industry Alcohol Processing

Alcohol Processing Cannabis Extraction

Cannabis Extraction Breweries, Wineries and Distilleries

Breweries, Wineries and Distilleries Cannabis Extraction Equipment

Cannabis Extraction Equipment Pharmaceutical Validation Products

Pharmaceutical Validation Products Getting the Perfect Crimp on a Hose Fitting

Getting the Perfect Crimp on a Hose Fitting Coding & Labeling Services

Coding & Labeling Services Product & Technical Services

Product & Technical Services Packaging & Drop Shipping Services

Packaging & Drop Shipping Services Quality Assurance Certification & More

Quality Assurance Certification & More Literature

Literature Part Number Library

Part Number Library Technical Articles/Documents

Technical Articles/Documents Informational Videos and Training

Informational Videos and Training Product E-Catalogs

Product E-Catalogs Case Studies – Product Innovations at Work

Case Studies – Product Innovations at Work Frequently Asked Questions

Frequently Asked Questions Rubber Fab eNewsletter Archive

Rubber Fab eNewsletter Archive